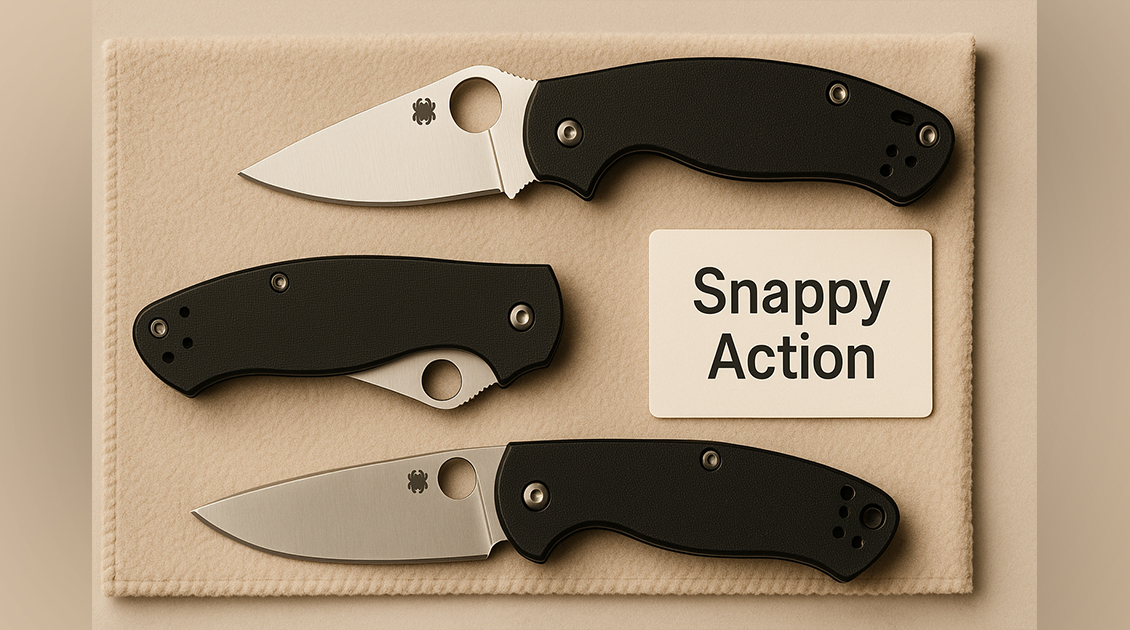

Weak Detent on Your Spyderco? How to Fix It for a Snappier Action

This is the 41th blog of the Spyderco blog series. You check the other blogs I wrote from here – https://spydercoparts.com/blogs

Author: Logan M. Fraser

Occupation: Custom Knife Modder & Spyderco Parts Specialist

Location: Calgary, Alberta, Canada

A weak detent on your Spyderco knife can make deployment feel sluggish, unreliable, and frustrating. The detent is one of the most overlooked parts of a folding knife, yet it plays a crucial role in how crisp the action feels. As someone who has modified and repaired countless Spydercos—from Para 3s to PM2s—I’ve seen how a tuned detent can transform a knife’s performance. In this blog, I’ll share how to diagnose detent issues, practical fixes, and upgrade options to achieve a snappier action.

Why the Detent Matters

The detent is the small ball bearing that sits inside the liner or frame, engaging with the blade to keep it closed until pressure is applied. It controls:

Retention: Prevents the blade from flopping open.

Crispness: Adds snap and consistency to deployment.

Safety: Ensures the blade won’t accidentally open in your pocket.

A weak detent can result in:

Mushy or lazy action

Blade partially deploying without intent

Flicking action that feels unreliable

For enthusiasts who love fidgeting with their Spyderco, a properly tuned detent makes all the difference.

Common Causes of Weak Detent

Factory Tolerance Variations

Spyderco does great QC, but sometimes detent strength varies across batches.Wear Over Time

Repeated opening and closing can polish the detent track, reducing bite.Aftermarket Mods

Blade swaps, washer replacements, or custom scales can slightly alter alignment.Pivot Over-Loosening

Over-loosening to get smoother action can unintentionally weaken detent feel.

Tools & Materials You’ll Need

Torx drivers (T6, T8, T10 depending on your model)

Quality replacement detent ball (ceramic upgrades available)

Cleaning supplies: microfiber cloth, Q-tips, isopropyl alcohol

Knife pivot lube (like Knife Pivot Lube)

Optional: fine diamond file or polishing tools for detent track

Note: Replacement parts such as detent balls and hardware can be found at SpydercoParts.com. These are precision-fitted to ensure compatibility.

Step-by-Step Guide to Fixing a Weak Detent

1. Disassemble the Knife

Use Torx drivers to remove the scales and access the detent mechanism. Keep screws organized.

2. Clean the Detent Ball and Track

Often, gunk and pocket lint can weaken detent engagement. Use alcohol and a Q-tip to clean thoroughly.

3. Inspect the Detent Ball

If it’s flat-spotted or worn down, replace it. Ceramic detent balls are a popular upgrade because they’re harder and give a crisper snap.

4. Polish the Detent Track

A light polish on the blade’s detent path reduces friction and improves consistency. Be gentle—removing too much material can worsen the issue.

5. Reassemble and Test

Put the knife back together, adjust pivot tension, and test the action. A small adjustment can make a big difference.

6. Consider Upgrades

If the issue persists, upgrading to higher-quality hardware can solve underlying tolerance inconsistencies.

Recommended Upgrades for Stronger Detent

Ceramic Detent Balls

Ceramic Detent Balls

Crisper engagement, longer wear life, and smoother action.

Titanium or Hardened Steel Liner Parts

Titanium or Hardened Steel Liner Parts

Stronger materials help the detent system last longer under heavy use.

These upgrades are designed to integrate seamlessly with Spyderco tolerances. Unlike generic aftermarket kits, parts from SpydercoParts.com are tested by experienced modders—ensuring fit and finish aren’t compromised.

When a Weak Detent Isn’t the Problem

Sometimes, issues that feel like weak detent are actually something else:

Loose Pivot: Blade wiggle can mimic weak detent.

Washer Misalignment: Can throw off engagement.

Dirty Track: Dust and debris reduce snap.

Always diagnose carefully before replacing parts.

Maintenance Tips for Snappy Action

Clean and lube every 1–2 months

Avoid over-lubing—it attracts pocket lint

Check pivot tension regularly

Store your knife in a dry, clean place

For ongoing maintenance, I always recommend keeping a bottle of KPL on hand. It’s specifically formulated for knife pivots and detent systems, unlike general-purpose oils.

Wrapping It Up: Why This Matters

Fixing a weak detent isn’t just about better action—it’s about trust in your knife. A tuned detent makes deployment more reliable, more fun, and safer. Whether you’re upgrading to ceramic detent balls, polishing the track, or replacing hardware, small tweaks go a long way.

This blog is part of my ongoing Spyderco series, where I share modder insights and hands-on fixes. If you want to dive deeper, check out my other blogs here: https://spydercoparts.com/blogs

Got a question about detent tuning? Drop it in the comments—I reply to every one. And tell me what you’d like to see next week: sharpening techniques, backspacer mods, or lockbar tweaks?